Lightweight insulation composite space truss roof board

Product synopsis:

Lightweight composite insulation space truss roof plate set of lightweight, high strength, durable, energy saving, thermal insulation, fire prevention, earthquake resistant, long service life, and many other excellent properties. The reliability of both the ordinary plate, the plate and absorbed the advantages of other new plate, highlights the structure properties, such as light, heat preservation and energy saving.

Product is mainly suitable for the environment of grade 1 and 2, industrial factory building, large warehouses, stadiums, water treatment plant, boiler room and conditions quite civil construction roofing, can be used with a variety of structures.

Execution standard: the structure of the national building specifications, procedures and standards

Atlas number: 2004 g701 \ liao liao 2010 g703

Patent no. : the lightweight composite insulation space truss roof plate zL 97 2 30327.8

Second, the product specifications:

Overall dimensions according to the requirement of practical use: 2000 ~ 4500 (plate across) x 2000 ~ 4500 mm (width)

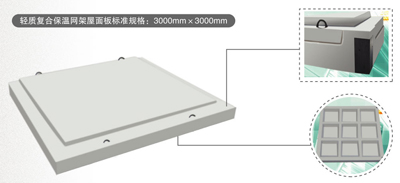

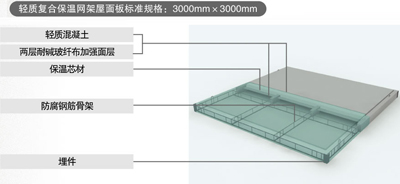

Suggested that as far as possible with a standard specification plate: 3000 x 3000 mm

Including arbitrary cullis boards and various kinds of specifications of the special-shaped plate (vertical plate, cornice, flood water orifice, missing Angle plate, triangle, a quadrilateral board and the modulus, according to the requirements of design and all kinds of heterotypic plates).

Plate generally is 160 ~ 240 mm, total thickness of insulation layer thickness can be adjusted according to different areas.

Three, product structure:

Consists of lightweight concrete, steel corrosion, alkali glass fiber cloth as reinforcing material compounded with guaranteed WenXin material. Main rib, rib and anti-corrosion steel skeleton and the plate surface, pouring the structure of form a complete system.

Four, product performance indicators:

Five, the product features

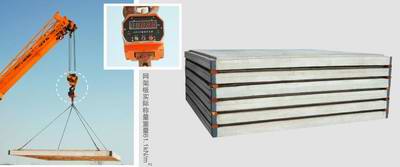

Light weight: per square metre weighs 60-80 kg, and built-in thermal insulation layer, need not be leveling; The weight is common reinforced concrete roof weight 1/4 ~ 1/3.

High strength, high strength, safe and reliable, practical test load to 3.92 KN/m squared and no crack.

Good seismic explosion: light weight, explosion performance is good, and the roof panel and the main structure welding, form whole rigid roofing, seismic performance reaches more than 8.

Durability: resistance to moisture, acid, alkali erosion effectively, service life can reach more than 50 years.

Bartender WenXin material: can be according to different regions, tailored. According to the specific project requirements, there are four options: flame retardant grade B polystyrene board, composite cement foam, rock wool, or rock wool + composite flame retardant grade B polystyrene board, can guarantee to achieve the requirement of the national fire protection.

Heat preservation performance is good: master section material in 70 mm thick cover WenXin material, for example, the actual detecting core material thermal resistance is 2.08 squared (m ? K)/W, has excellent heat preservation and heat insulation performance, fully meet the national requirements for energy saving heat preservation.

Refractory limit: the national fire authorities detection can reach 1.5 ~ 2 hours.

Installation quick and easy to use: plate type specifications made based on the characteristics of the building, the hole can be reserved when plate production, convenient in installation.

Waterproof construction is simple: the roof plate does not need to do roofing leveling layer, can be directly to do waterproof construction.

Economic benefit is obvious: can obviously save the amount of steel structure system, shorten the construction period, the comprehensive economic benefit is obvious.

Six, BaoWenWu panel installation

Generally can be used cranes and crane hoisting, the multi span, large-span industrial factory building adopts rail car transport installation. Single class installation of up to 1000 ㎡ / day

1) plate lifting in place to ensure uniform flat roof plate, plate seam.

2) each roof plate and plate to ensure no fewer than three welding, butt welding is less than the Angle of the hook will be here with the steel reinforcement and the adjacent plate hook welding. Plate on the steel structure strut length shall ensure that not less than 60 mm, welds shall not be less than 5 mm.

3) joints processing according to design requirements.

Using the matters needing attention

1) board should avoid sharp heavy impact, trolley should not be direct cargo traffic construction, must be spread by adopting the method of laying plate concentrated load.

2) not as civil construction operation, i.e., unfavorable and erection of scaffolding on the roof, to avoid concentrated stacking heavy objects. Take the corresponding protective measures when necessary.

024-89874245

024-89874245