My company is involved in the compound insulation cladding (atlas number: liao 2013 g704) preparation work.

Composite insulation cladding is divided into ordinary insulation wallboard and fiber reinforced cement composite board.

A brief introduction, product structure

Do ordinary insulation wallboard: is reinforced for bearing steel, glass fiber grid cloth as reinforcing material, to match the light aggregate admixture as aggregate, top and bottom surface with alkali resistant glass fiber grid cloth as reinforcing material, with guaranteed WenXin material compound, main rib, rib by concrete and steel frame and plate the surface of cast-in-place structure of form a complete system.

Classification: the flat composite wallboard (PKB), open a composite wallboard (QKB) in two forms

Features: factory production, on-site assembly, with light weight, high strength, thermal insulation, energy saving, quick construction.

Purpose: the flat composite wallboard (PKB), is applicable to industrial plant, power plant, boiler room and other large industrial buildings.

Open a composite wallboard (QKB) used in civil and industrial building wall.

Fiber reinforced cement composite panels, panel for 5-8 thick, is based on high quality high grade cement base material and natural fiber reinforced, sandwiching WenXin material, combining binder will be up and down surface and core material into a whole.

Features: explosion, high strength, energy saving, fire prevention, waterproof, corrosion resistance, sound insulation, can be sawed, improve construction efficiency, etc

Second, the bartender WenXin material: according to the specific project requirements, there are four options: flame retardant grade B polystyrene board, composite cement foam, rock wool, or rock wool + composite flame retardant grade B polystyrene board, can guarantee to achieve the requirement of the national fire protection.

Three, product specifications

Ordinary insulation panels, according to actual use requirement design plate type, thickness is 140 mm - 320 mm, can be adjusted according to the different load and span requirements, the largest span 9 m.

Fiber reinforced cement composite board, standard specifications 2400 * 1200 * 60-120 - mm.

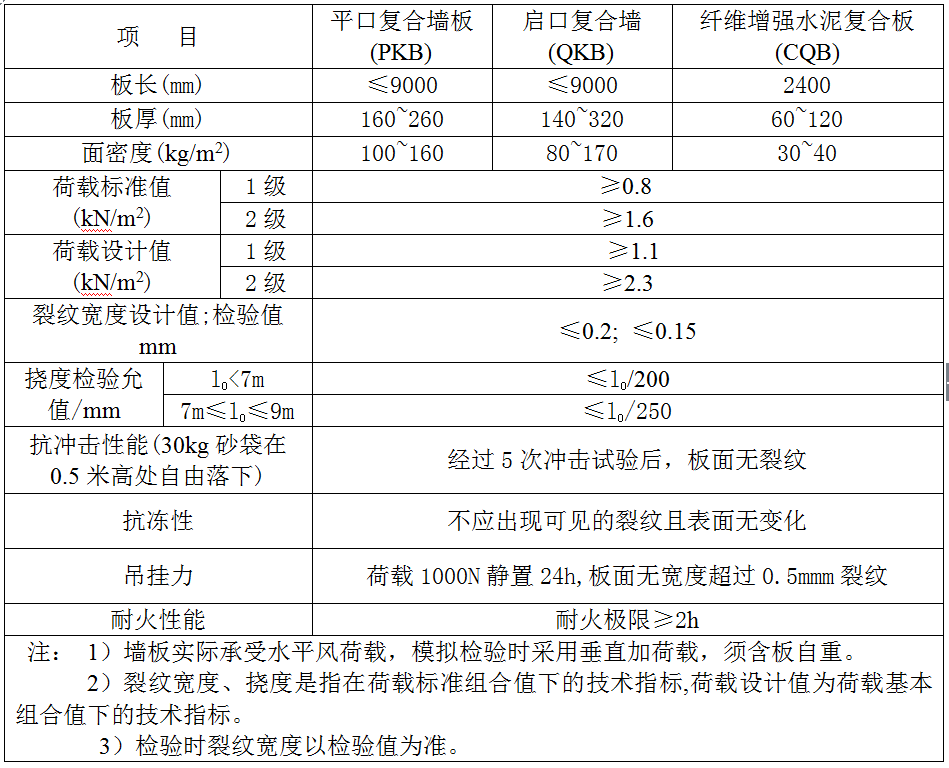

Four, product performance indicators

Project (PKB), open a composite wall flat composite wallboard (QKB) fiber reinforced cement composite board (CQB)

Plate length (mm) or less, 9000, 9000, 2400 or less

Thickness (mm) 160 ~ 160, 140 ~ 320, 60 ~ 120

Surface density (kg/m2) 30 ~ 40 100 ~ 160, 80 ~ 100

Load standard values (kN/m2) grade 1 0.8 or higher

2nd level 1.6 or higher

The load design value (kN/m2) grade 1 1.1 or higher

2nd level 2.3 or higher

Crack width design values; Test value of 0.2 mm or less; 0.15 or less

Deflection test done value/mm l0 < 7 m l0/200 or less

7 m or less l0 9 m or less l0/250 or less

Shock resistance (30 kg sandbag in the 0.5 m high free fall) after impact test 5 times, board face no crack

There should not be a visible crack frost resistance and the surface without change

Hanging force load of 1000 n stand for 24 h, board face no wider than 0.5 MMM crack

Refractory refractory performance limit 2 h or more

Note: 1) the wallboard horizontal wind load, the actual analog test when the vertical load, should include board weight.

2) crack width, the deflection is refers to under the load combination of standard value of technical indicators, load design value of load under the combination of basic value of technical indicators.

3) inspection when the crack width will be subject to inspection value.

4) see deflection limit deflection test done.

Five, the installation instructions

1, the common thermal insulation panels and light weight aggregate concrete large panels, according to the wall panel installation layout, after plate lifting in place, and to set up for welding structure.

2, treatment of joints according to design requirements carefully. Lightweight aggregate concrete, fiber reinforced cement composite board didn't plaster, ordinary insulation wall plate layered plaster, again according to the construction of performance, to brush paint, wall tile, etc, adopt flexible putty and elastic coatings.

3, equipment attached to the wall is fixed: electrical, bathroom hangs, etc., shall not use hammer impact gouged wall, and rib plate, reaming drill bit. Hanging on the wall around the embedded parts, must be full of binding material, to ensure the secure anchorage.

4, heat is not allowed to hang on the wall, can be used with bearing heating, the heating weight to the ground, use electric drill hole, hole full fill bond, embedded support, to ensure lateral stability.